blown film machine specification

Blown film machine specification Monday May 2 2022 Edit. ABA Blown Film Machine.

Co Extrusion Blown Film Line Internal Bubble Cooling System Ibc

Specification Of Monolayer Two Layer Three Layer Extruder Machines.

. The film may be laminating film shrink film agricultural covering film bags or film for textiles and clothing and other packaging materials. A film blowing machine involves one process used to make plastic film. We also make extrusion line for hm pp pvc hips etc.

Along with PP HDPE LDPE LLDPE blown film machines types of pellet machines and flexo. LDPE Blown Film Machine You can Buy good quality LDPE Blown Film Machine we are LDPE Blown Film Machine distributor LDPE Blown Film Machine manufacturer from China market. No matter HDPE LDPE or LLDPE A B A three-layer coextrusion film blowing machine has its unique material characteristics.

The two layer film blowing unit can continuously blow various LDPE HDPE LLDPE mLLDPE EVA and other composite packaging films with different width and. These products have gained widespread recognition for their efficient performance longer functional life smooth. The different layers are used for different properties such as a barrier layers layers for reclaim plastic or fill or UV stability.

Model For ABA Specification. Sturdy and reliable the Blown Film Plant Machine Series has a solid performance record. This is caused by the slower cooling process that allows the blown film molecules to spread out instead of aligning as they do in cast film.

Our monolayer blown film machines incorporate advanced features like-grooved feed barrel barrier screw dosing system manual as well as automatic screen changer Rotating Die platform internal bubble cooling automatic bubble cage online thickness monitoring and control 2 4 station surface and center winders Auto tension control Corona treaters etc. Atlas Development Machinery Co Ltd since 2004 is a Heavy-Duty Blown Film Machine manufacturer based in Taiwan. 5 rows We are offering high speed blown film Making Machine.

Established in the year 1993 we are a well-known manufacturer supplier and exporter of Plastic Extrusion Machinery. MODEL DYL-45B DYL-45B DYL-55B DYL-65B MATERIAL LDPE LLDPE FILM WIDTH 300-600MM 300-800MM 400. Blown film is actually tougher and has less of a chance of puncturing than cast film.

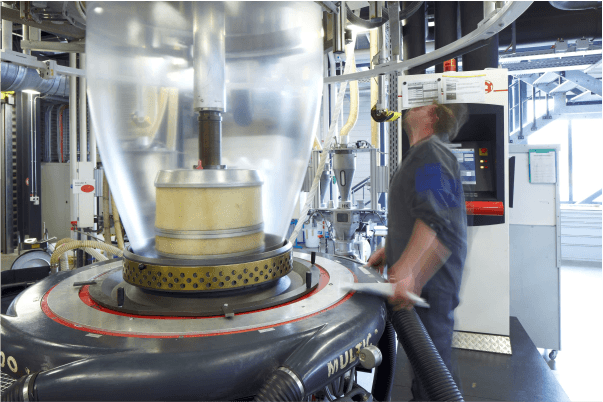

Efficient cost-saving and high output all Atlas Machinerys extruder machines are designed to deliver the best quality of plastic films. Compact Type Blown Film Machine The MB mini-type blown film machine is suitable for general packaging prod- ucts such as T-shirt bags supermarket bags flat bags and many others. Berg BFC Operating in a Blown Film Extrusion Line.

We provide fully automatic turnkey projects with extrusion cutting and sealing and punching machines. Blown film can be a few centimetres to more than three metres across and can range from a single layer to up to ten layers of material. Blown film lines require lower melt temperatures.

Our blown film portfolio offers the right machine for your individual production needs. 150 mmin Automatic reel change over and automatic web cross-cutting mechanism Expander roller - PolybandBanana European gear drives Load cell for. Film width available from 150mm to customized depending on customers requirement suitable for both HDPE The special screw design provides good mixing for both colored with.

WH blown film lines are designed especially for the flexible packaging industry. Film width available from 800 mm to 2300mm and can be customized depending on customers requirement suitable for both HDPE and LDPE film. We make machines fir 4 inch to 24 ft wide baloon.

Monolayer Blown Film Machine gives high output up to 280 kghr with thickness ranging from 8 microns to 150 microns and a maximum film width of 2500 mm. Home About Us Products. Through multi-layer coextrusion the physical strength of the film is improved and the internal and external materials supplied by the host machine are used which can reduce the structure of the main body and reduce the cost and.

Air shaft-Trim suction-Heat Exchanger-Melt pressure indicator-chiller - Dotaco - Plast Control. Also cast unwinds quieter and is easier to. LDLLDPE HIGH SPEED FIM BLOWING MACHINE Main Specification.

Film width available from 800 mm to 2300mm and can be customized depending on customers requirement suitable for both HDPE and LDPE film. Blown film towers require large vertical heights. Film Width from 150650mm.

Our range includes Plastic Extrusion Plants Multilayer Blown Film Extrusion Plants Monolayer Blown Film Plant Two Layer HM Blown Film Plant. And we also made plastic bag machine blown film machine bag sealing machine blowing machine hand bags machine poly bag making machine and so on. Monolayer 1 Layer Two Die Heads Single Screw.

This is caused by the slower cooling process that allows the blown film molecules to spread out instead of aligning as they do in cast film. HM LD LDPE Monolayer Two Layer Three Layer Extrusion Plant ABA Two Three Layer Multilayer Mulching Paper Film Plant Garbage Bag Plant Blown Film Plant Liner Film Plant. The specially designed blown film extruder has good ability for melting and mixing material with masterbatch additives.

Die design ensures good color separation for each layer. We are mfrs and exporters of blown film lines for making carry bags garbage bags tirpal munch film we make mono layer multi layer multi colour aba films. Hopper loader - Hopper loader with dryer-Corona trater-Lever type screen changer.

Carry bags AIr Bubble Sheet Tirpal. Blown films provide a better balance of properties between the machine and transverse directions. The blown film process can produce a wide range of film sizes from the same die.

We are producing blown film lines since 1967 and have consistently set new standards such as the development of the internal bubble cooling system and the oscillating haul-off. SPECIFICATION SUITABLE MATERIAL HDPE FILM THICKNESS 008-010MM FILM WIDTH 6-14INCH FILM OUTPUT 35-70KGSHR AUTO THEMO CONTROL 10 ZONE EXTRUDER SCREW DIAMETER 55MM SCREW LD. Works with virgin recycled and CaCO3.

The AB type two-layer film blowing machine is equipped with two extruders which can produce two layers of film each layer of material color is different. Blown film lines are used to make shrink wrap films. Extruded tubular processing is most often used with polyethylene films but can be used with other polymers.

Film Winders Semi-Automatic Winders Two station semi-automatic surface Online reel changeover without any Bow roller provided as expander roller Option of auto-tension control Fully Automatic Winders Line speed - Max. Twin Head Blown Film Machine. One Layer Twin Head HDPE LDPE 650mm.

Cast machine cast wrap has a glossier clearer finish which allows different scanning technologies to be used. Monolayer Blown Film Machine is a cost effective investment of producing single.

Blown Film An Overview Sciencedirect Topics

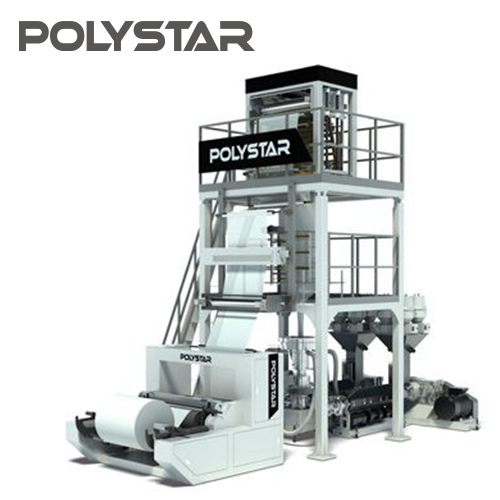

Two Layer Blown Film Machine Polystar Machinery

Hdpe Blown Film Machine Polystar Machinery

Blown Film Extrusion Plastic Extrusion Systems Compounding Pelletizing Profile Pipe Film Manufacturer Intype

Blown Film Plant Three Layer Blown Film Line Non Ibc Ibc

Three Layer Aba Blown Film Machine Polystar Machinery

Process Cooling Blown Film Coolers Berg Chilling Systems

Blow Film Machine Film Blowing Machine Polystar Machinery

Blown Films Extrusion Windsor Machines Limited Pdf Catalogs Technical Documentation Brochure

Wenzhou Aoxiang Packaging Machinery Co Ltd

Process Cooling Blown Film Coolers Berg Chilling Systems

Plastic Film Extrusion Machine Plastic Blown Film Extrusion Machine Extruder Machine Manufacturers

Three Layer Aba Blown Film Machine Polystar Machinery

Blown Film Machine Blown Film Line Fki Machinery

Aba Co Extrusion Blown Film Machine Prm Taiwan B2b Marketplace

Pe Blown Film Extrusion Machine Plastic Blow Film Machine Pe Plastic Film Blowing Machine Real Time Quotes Last Sale Prices Okorder Com